1. What is a ribbon blender : definition

Ribbon blenders are made of shell having a U shape in which is rotating an agitator. The agitator is designed as a double helical ribbon which allows to create convective movement of the materials in 2 directions achieving mixing of powders and bulk solids.

Ribbon mixers are very widespread in process industries for bulk solids dry Mixing. Although other Mixers designs exist which are over-performing ribbon blenders in some areas (mixing speed, hygienic design…), ribbon blenders are still a very simple and robust solution to mix dry materials offering decent mixing performances which are sufficient for many applications. It is not rare to have 40-50 years old industrial ribbon blenders in factories, still perfectly operational. Many manufacturers propose industrial ribbon blenders, from few hundreds liters to several cubic meters.

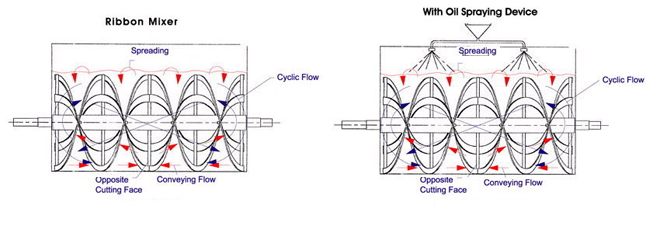

Ribbon Blender Working Principle

Horizontal ribbon blender working Principle. No Gravity Mixer Horizontal cylinder with bi axial rotation reverse the pulp, the blade into a certain angle of the material along the axial, radial cycle stir, so that the material quickly mixed evenly The speed of the shaft and the structure of the blade will weaken the weight of the material.

With the lack of gravity, the difference of the particle size and the proportion of the material is neglected during the mixing process. The intense mixing movement shortens the time of mixing, faster and more efficiently.

Even if the material has a specific gravity, the difference in particle size, in the staggered arrangement of the stirring blade quickly under the sudden somersault throwing, but also to achieve a good mixing effect.

2. Ribbon blender discharge

Horizontal ribbon mixer discharge way : use of pneumatic materials in the form of large open door, with the discharge of fast, no residue, etc.; high-fineness of materials or semi-fluid materials using manual butterfly valve or pneumatic butterfly valve, manual butterfly valve , Pneumatic butterfly valve on the semi-fluid seal is good, but the cost is higher than the manual butterfly valve. In the case of heating or cooling, the jacket can be configured.

Heating methods are electric heating and heating oil heating two options: electric heating convenient, but the heating rate is slow, high energy consumption; heat oil heating need to configure the oil pan and oil power, pipe, investment, but the heating speed , Low energy consumption.

Cooling process can be directly into the jacket into the cooling water, jacket heat transfer area, cooling speed. Motor and stirring between the spindle through the cycloid reducer direct connection, simple structure, high reliability, easy maintenance.

3. Ribbon blender application

Ribbon blender machine widely used in pesticides, veterinary drugs, food, chemicals, biological, aquaculture, ceramics, refractories, plastics, fertilizer and other solid – solid (ie powder and powder) solid – And glue slurry), but also particularly suitable for thick material mixing.

Advantages of Ribbon Blender:

- Ribbon blenders can be operated in both batch and continuous modes.

- High shear by baffles cause break down of aggregates

- Less head space requirement

Disadvantages of Ribbon Blender:

- It is practically difficult to obtain 100% discharge in the ribbon blender.

- Higher clearance between the external periphery of the outer ribbon and the container may result in unmixed or dead spots.

- The movement of ribbons near the vessel walls due to high shear and compression can damage fragile materials and cause attrition.

Variant of Ribbon Blender:

- An alternate design of the ribbon agitator is the paddle agitator which can handle a fragile material. The paddle agitator is composed of both forward and reverses paddles in place of the ribbon. The paddles are positioned to move the material in opposing lateral directions as well as in a radial direction. The paddle design is generally used when friable materials are mixed, and when batches as small as 15% of the total capacity are going to be blended into the blender

Pharmaceutical applications:

- A ribbon blender is used for blending large volumes of dry solids, wet solid mass, bulk drugs, chemicals, and cosmetic powders.