DRUM FLAKER MACHINE

Drum Flaker / Drum Drier are used to make flakes continuously from molten material. The molten material to be flaked is poured on the tray of Flaker which get solidified on the surface of rotating drum which is scraped to get flakes of desired thickness.

We manufacture Drum Flakers of various capacities depending on the production of flakes required.

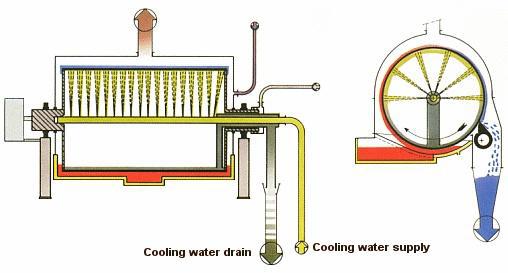

Cooling Drum Flaker consist of Drum fabricated from Mild Steel or Stainless steel with hollow shafts on both ends. The drum surfaced is duly ground and hard chromed with superior finish to get uniform thickness of the flakes. The drum is provided with a Hollow Shaft for entry of water for sprinkling on the inside of the drum for cooling purpose.The drum is mounted on self aligning spherical roller bearing for smooth rotation and to take care of scraping loads.

A jacketed feed tray is provided below the drum in which molten material is poured, the molten material gets coated to the drum by a sizer pipe.The Scraping arrangement is made of Copper or Fiber Blades to scrape the flakes. A discharge tray is provided to collect the Flakes.

Description:

- DRUM FLAKER are used to convert molten products into solid in to continuous operation. Molten feed adheres on to the outer surface of rotating drum through feed tray / applicator Roller. To avoid solidification of feed melt on the tray, it is provided with limpet coil or jacketed provision to maintain the heating by steam, thermic fluid or hot water.

- Drum is internally cooled by spraying chilled / cooling water through spray nozzles. To avoid leakage of cooling water medium, PTFE rope or Mechanical Seal is provided for rotary joint. The product solidifies and after completion of rotation of drum scrapped off the drum surface to form flakes.

- Cooling drums and other feed contact parts: They can be decided as per constituent properties of feed product & choice of end user. In case of process requirement the cooling drum can be chrome plated.

- Material of construction of contact parts:Carbon steel, SS 304, SS 316, SS 316 L , others upon request

- Cooling Drum Sizes: 0.5 Sq.Mtr to 30 Sq.Mtr.

- Type of Feed Mechanisms:

Single Drum Flaker- Bottom Dip Feed

Single Drum Flaker- Bottom Applicator Roller

Single Drum Flaker- Overhead Applicator Roller

Double Drum Flaker- Nip Feed (others upon request)

- Scrapper Blade arrangement: Manual hand wheel / Pneumatic / Hydraulics

- Scrapper Blade MOC: Hylam, Phosphor Bronze, Magnesium Bronze, Brass , Food Grade Teflon and others

- Product Collection: Post solidification of the feed material the flakes can be collected via product collection chute or hopper or gets discharged via lump breaker /screw conveyor discharge outlet which can be directly filled into drums or bags.

- Compliance: We can manufacture the drum flaker equipment as per GMP and Food grade compliant in case specific requirement from customer.

Drum flaker Machine

| Item No. |

Specification

mm

|

Motor Power

Kw

|

hot Barrel speed

r/min

|

Size (mm) | ||

| L | W | H | ||||

| DZ-1 | 600×600 | 2.2-3 | 0.3-15 | 2400 | 1480 | 1410 |

| DZ-2 | 800×1200 | 3-5.5 | 0.3-15 | 3360 | 2000 | 1600 |

| DZ-4.5 | 1200×1200 | 5.5-7.5 | 0.3-15 | 3730 | 2250 | 2050 |

| DZ-7.5 | 1400×1800 | 5.5-11 | 0.3-15 | 4460 | 2460 | 2350 |

| DZ-9 | 1600×1800 | 7.5-15 | 0.3-15 | 4460 | 2600 | 2550 |

| DZ-22 | 2300×3000 | 11-18.5 | 0.3-15 | 7200 | 3900 | 2350 |